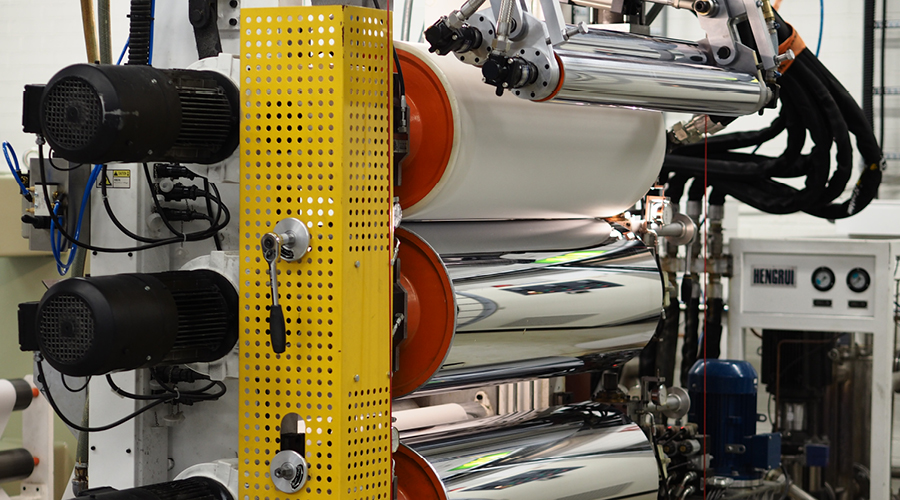

In order to meet the market’s needs for thinner environmentally friendly plastic film, the innovative company Scanfill AB has invested in a machine change to broaden its product range of fully or partially oil-free plastics. By replacing one of the steel rollers in the manufacturing process with a rubber roller, Scanfill AB has reduced its minimum range and now has the capacity to produce the environmentally friendly plastic film Scanfill Sheet with a thickness of 150 microns up to 1500 microns.

– We constantly strive to develop our Scanfill products to meet the growing demand, says Karl Banke, development engineer. With the thinner Scanfill Sheet, we open up for more applications for both existing and new customers.

Scanfill Sheet consists of 50% minerals, giving it many advantageous features in addition to the superior environmental benefits. The minerals give the material excellent strength and stiffness, which allows for a thinner film. In addition, Scanfill Sheet has a naturally effective barrier, which can be further enhanced by including an EVOH layer.

– Scanfill Sheet is available in up to seven layers, with different colors, and with matte or shiny surface layers. We look forward to exploring the many different uses of Scanfill Sheet together with our customers”, concludes Karl.

Scanfill AB offers cost-effective and durable packaging materials consisting of 50% minerals and 50% polyethylene or polypropylene which adds strength and impact resistance. The Scanfill materials are approved for food contact, have high heat conductivity, excellent molding properties, and provide increased production speed.