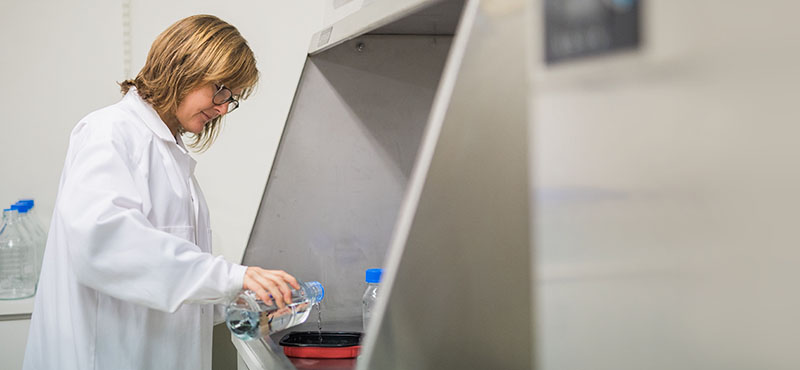

Laboratory

Scanfill has a very well equipped and modern laboratory. We have access to a number of tools that can help the customer with the design and manufacture of their product.

We can cater for the customer’s requirements both in terms of form and color, and also the appropriate sealing properties according to the customer’s unique needs.

Click on our test methods below for more information, and read more about our prototype development.

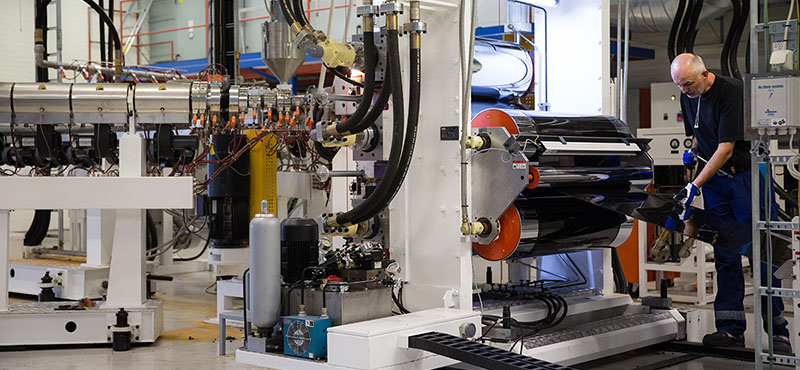

Thermoforming machine

There is around a dozen different moulds you can use for creating packaging in our thermoforming machine. Here we initially...

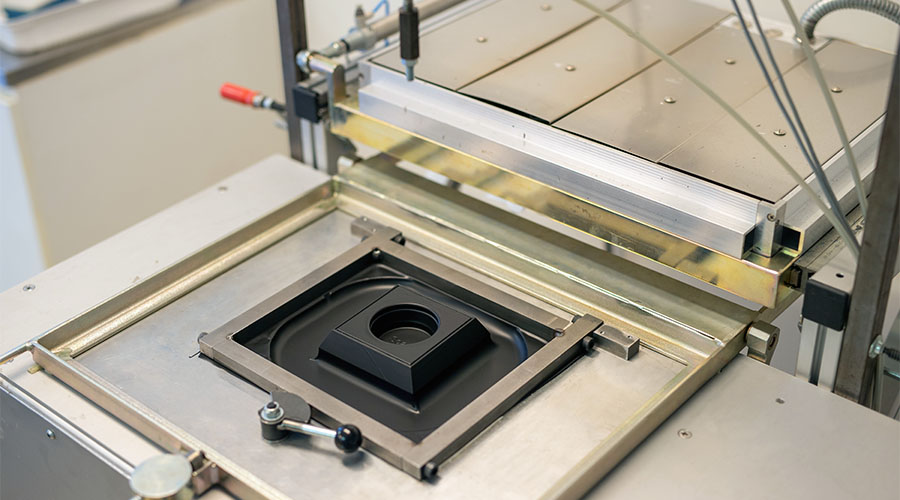

Test packing

If you wish to pack your product in order to test any specific properties, we have the ability to do this in a couple of standard formats...

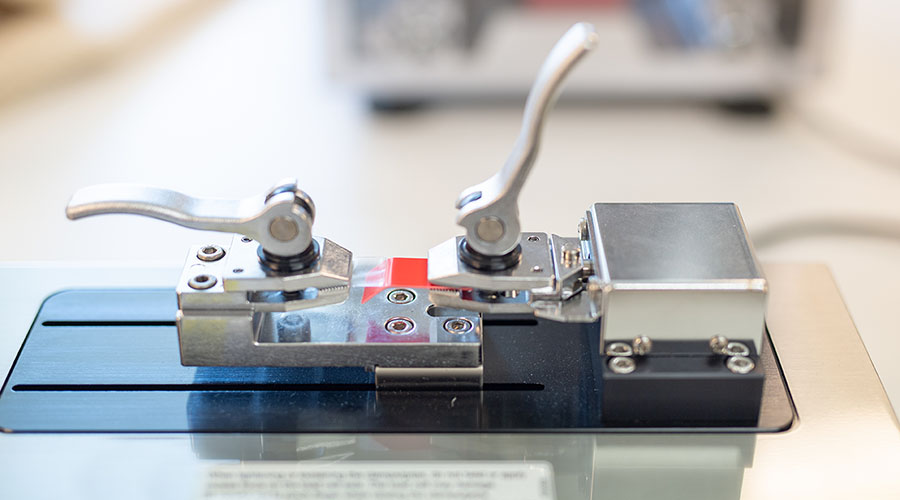

Peel and seal test

We deliver a seal uniquely designed for the customers’ needs and we have the equipment to test and secure the sealing properties...

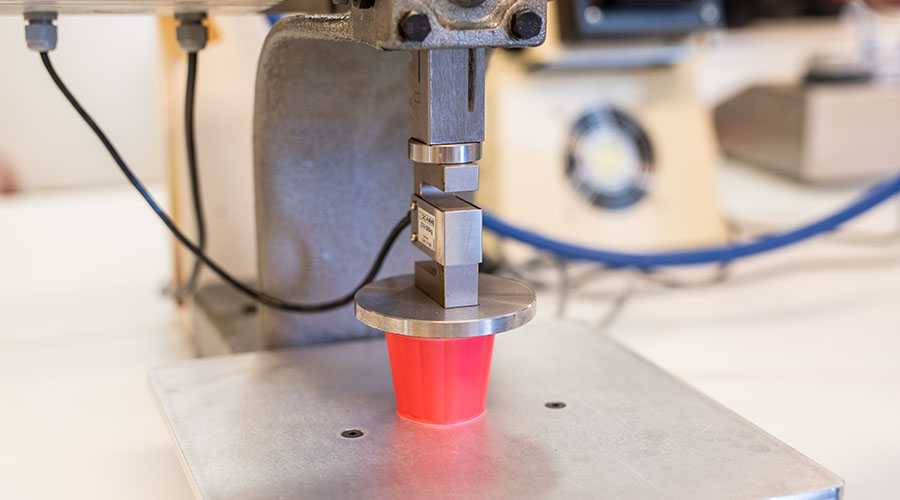

Top load

Top load is tested as part of the validation of the packaging and it measures the maximum weight a packaging can bare before...

Climate simulation

We can do climate tests of the packaging in order to measure how they will manage a transport under extreme temperatures...

Migration test

In the laboratory we measure and evaluate migration during our development of the material. We do this constantly...

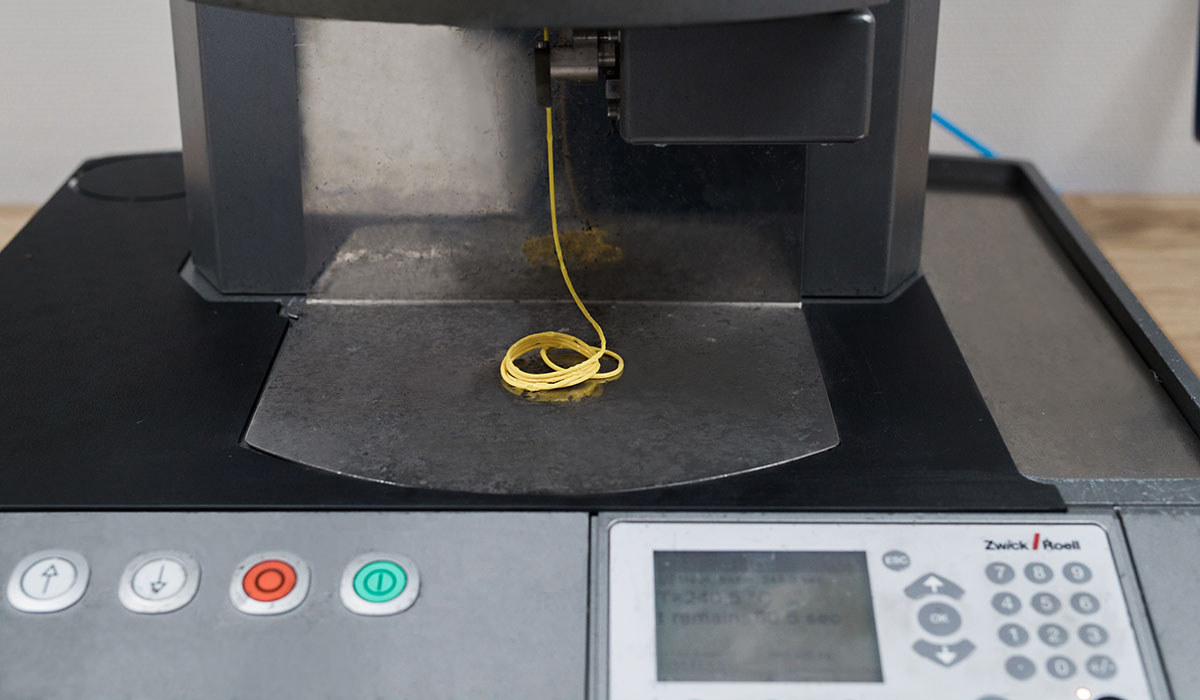

Tensile and flexural test

By putting pressure on test specimens with certain power under a special amount of time, we can test the flexural and tensile...

Color measurement

To guarantee a thorough measuring of all colors, we use a spectrophotometer. This equipment measures according to...

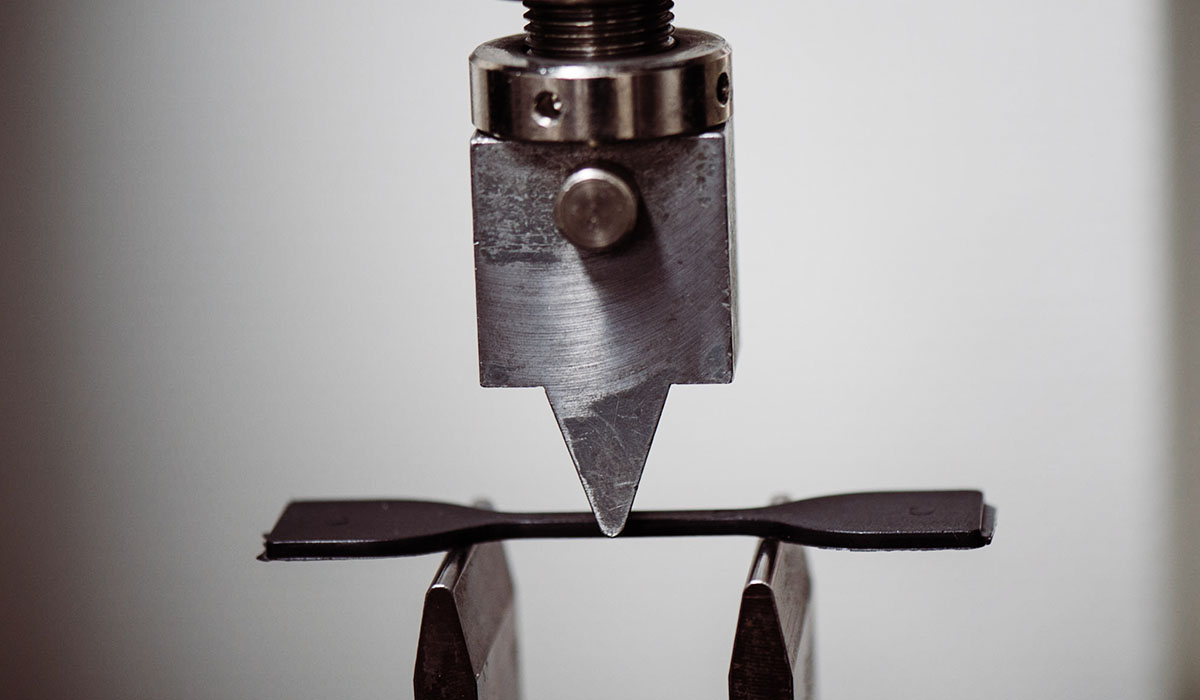

Charpy (Impact strength)

To measure how impact resistant a material is, the test specimen is hit by a pendulum, where the impact resistance is measured...

Melting index (MFI/MFR)

The most frequently used method of measuring the flow ability of a material is the melting index. The material is melted...

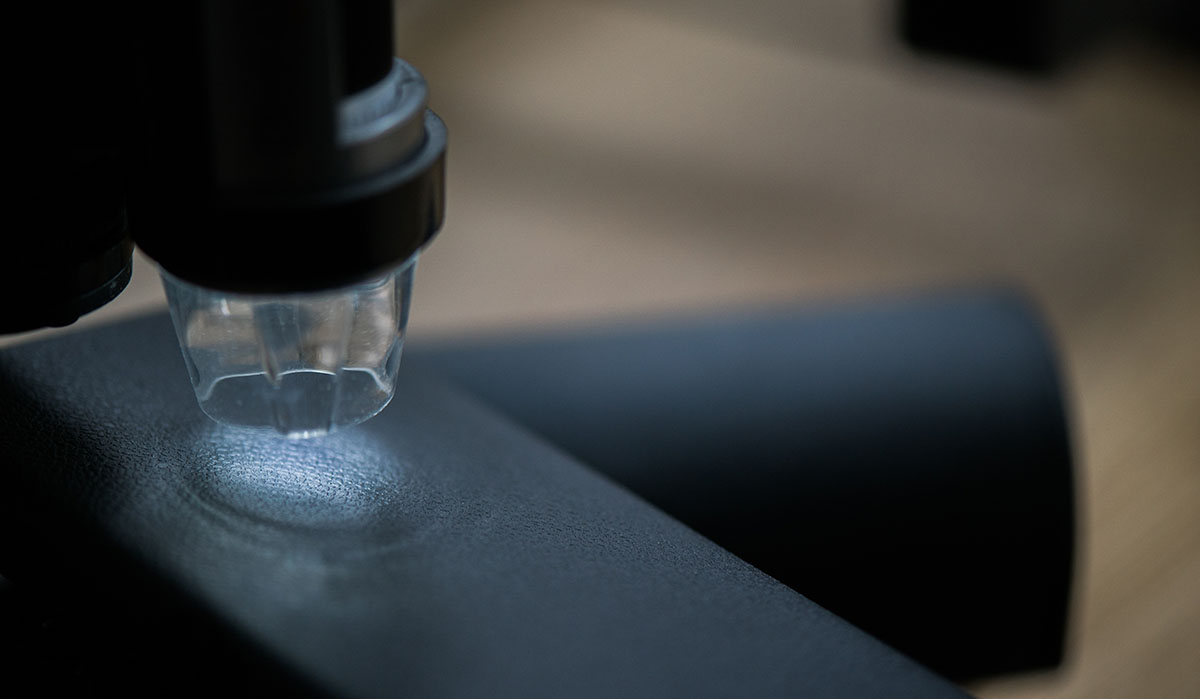

Light-microscope

In order to watch and analyze a material deeply, we use a light-microscope where we zoom in on surfaces and cross sections...

FTIR

With FTIR you are able to show what polymers, reinforcements and additives are used in a material - like the “fingerprints”...

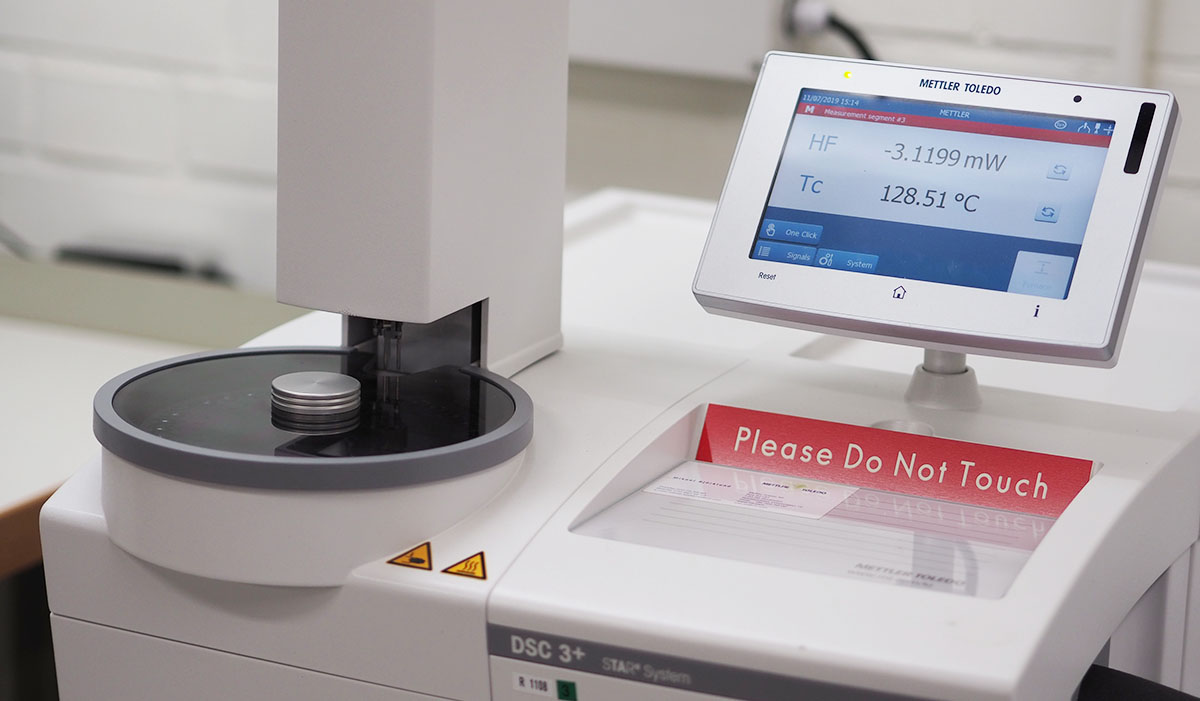

DSC

The crystallization temperature (Tc) and the glass transition temperature (Tg) of a material can be measured by a DSC-equipment...