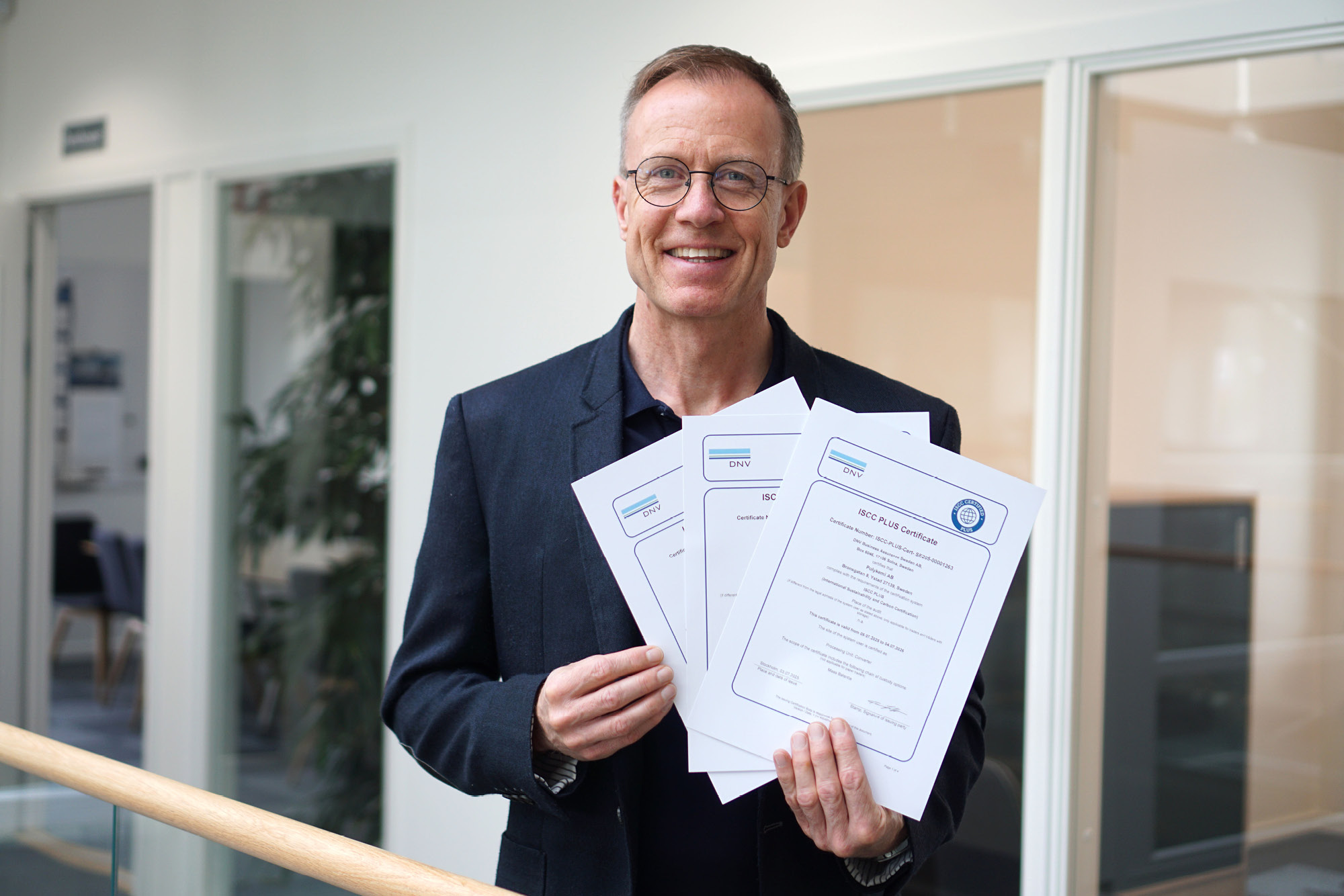

Recently, Polykemi, Rondo Plast, and Scanfill had our ISCC PLUS certifications for recycled mass-balanced plastic raw materials confirmed. The certifications apply to the facilities in Ystad, Sweden, giving all of Europe access to certified high-quality recycled plastic materials. The certification process has been an essential step in the ongoing development towards increased sustainability and reduced carbon footprint.

Recycled plastic materials become certified traceable

The newly awarded ISCC PLUS certification mean that Polykemi, Rondo Plast, and Scanfill (Polykemi Group) in Ystad, Sweden, can now provide a certificate to customers that guarantees the traceability and amount of recycled mass-balanced plastic raw material in delivered materials. Customers can use this information in their own calculations and reports.

Polykemi and Scanfill already hold ISCC PLUS certifications for bio-circular mass-balanced plastic raw materials.

“The process to become certified for recycled materials is somewhat more complex and involves stricter controls – for the right reasons – so we are very pleased to have achieved certification for recycled materials as well,” says Mattias Persson, Chief Commercial Officer at Polykemi Group.

Overlapping systems guarantee the exact amount of recycled raw material

Traceability is nothing new for Polykemi Group, which has extensive experience in careful supplier monitoring and evaluation.

“We have used our own ERP system for a long time, that provides traceability for all our materials. This means our customers can receive confirmation showing the exact amount of recycled raw material in the purchased materials, in addition to the ISCC PLUS certificate,” says Mattias Persson.

Certified responsible production in an unbroken chain

Apart from documentation showing the proportion of recycled raw material in the finished plastic material, the ISCC PLUS certificate also serves as a proof of increased transparency and reflects the supplier’s quality and sustainability efforts – from source to buyer.

“Certification of recycled content and its origin is becoming increasingly important – not only for customer transparency but also from a legislative perspective. By certifying the content, we increase our credibility while meeting future requirements,” says Mattias Persson.

The certification includes requirements that materials from different sources maintain the same high quality in an unbroken chain and that they are produced in a responsible manner aiming to, among other things, reduce our own carbon footprint.

“Certification for both current and future raw materials in the same system allows us to provide our customers with not only certified but also cost-effective and optimized materials. It becomes easier to combine our sources to give our customers the best options,” says Mattias Persson.

A natural step to stay at the forefront

The certification applies to the sale of certified materials based on recycled plastic raw materials from certified sources where the raw materials come from post-industrial (PIR) or post-consumer (PCR) origins. Industrial plastic waste is available from many certified suppliers today, but suppliers certified for consumer sources are significantly fewer.

“We are ahead of the curve – even preceding PCR suppliers – but this means that we will also be able to be among the first to receive raw materials from them as soon as it becomes possible,” says Mattias Persson.

With the certification secured, Polykemi, Rondo Plast, and Scanfill stand ready, already prepared before some of the suppliers, to secure market position and continue offering customers proven high-quality recycled plastic materials.

“Working on this certification has been a natural step for us. It is not a final destination by any means, rather a step forward meaning we are now well-prepared and have greater flexibility for the future, allowing us to constantly strive to become even better,” says Mattias Persson.